Robotic Automation

Optimizing safety and efficiency in your corrugated folding carton operation starts with letting us improve your processes through application of our robotic automation solutions.

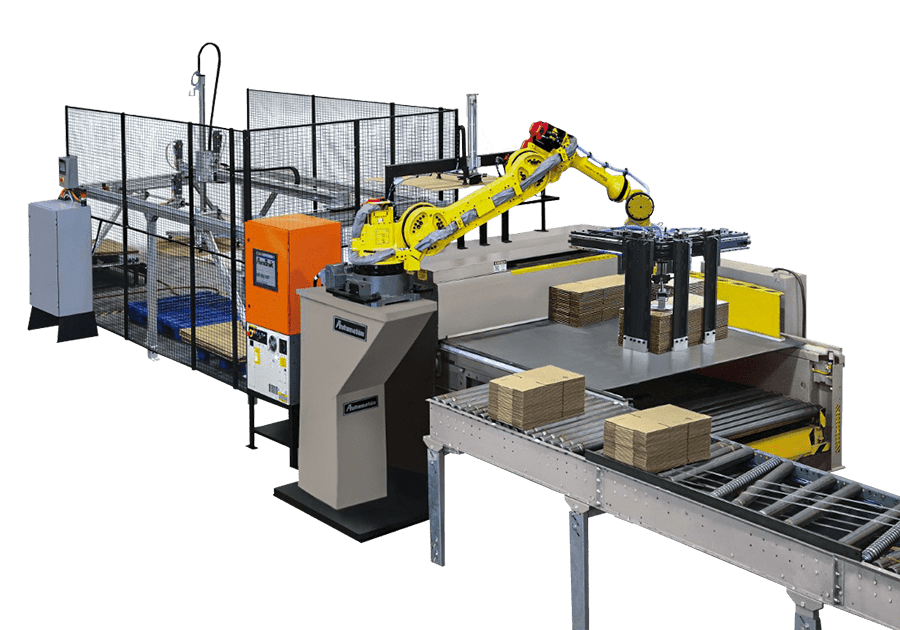

AutoStak Robotic Load Former

The AutoStak Robotic Load Former is responsible for transferring bundles of corrugated material from the inbound conveyor system to an Automatan or customer-supplied load former utilizing the End-of-Arm Tool (EOAT) and custom programming. The AutoStak Palletizing EOAT is responsible for transferring the corrugate bundles from the outbound conveyor system to the palletizing area utilizing paddles. The AutoStak conveyor section will justify the bundle to the proper position on the conveyors, move the bundle into the AutoStak robotic bundle feed section, and then assist the robot in transferring the bundle into the Automatan’s or the plant’s load former, in the proper position for each specific layer pattern.

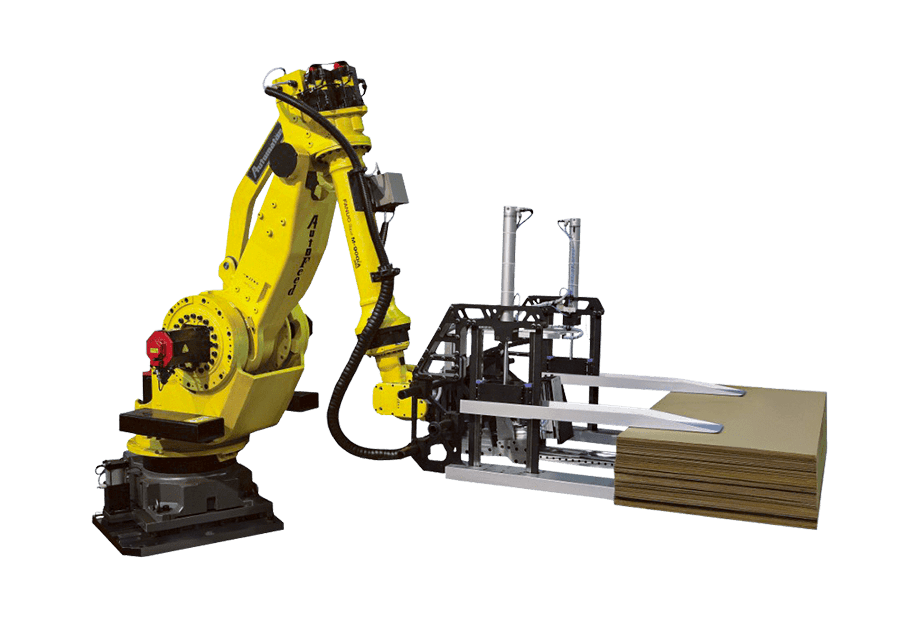

AutoFeed Robotic Feeding Solution

The AutoFeed Robotic Feeding Solution is responsible for transferring the corrugate material from the inbound conveyor system to the board feeder utilizing the end-of-arm tooling. Automatan AutoFeed systems have capability for 360kg and 750kg loads, and are designed for application on most commercially available FFG systems. The device consists of the robot, end-of-arm tool, backstop, and all associated controls to fully automate the loading process. The end-of-arm tool is responsible for segregating and securing a predetermined stack of corrugate material up to 14" in height during the transfer from the inbound conveyor system to the board feeder. Benefits include reduced manual labor, increased uptime and efficiency, a small footprint (it can save over 50% floor space from conventional pre-feeders), versatility (the ability to feed multiple machines), and six axes of motion to enable board flipping as well as nearly any layout configuration.

Support Services

Technical Support Services

Find the latest upgrades and improvements available for your Inspire Automation equipment.

- Remote Technical Support: M-Guard and AutoView Remote Monitoring Systems

- Inspire Advantage Program: Long-Term (Annual) Service/PM Program

- Service Audit Programs

- After-Hours Service Support

- Remote Service Technology

Product Support Services

Get support relating to the specific products currently being used in your operation.

- Spare Parts Packages

- Dedicated Spare Parts Fulfillment Center

- Support for Other OEM Products

Product Features and Benefits

Our product features enable you to maximize the operation and efficiency of your equipment.

- Fewer Direct Connect Drives

- ASI Framework—Less Wiring

- Less Hardware with Welded Frames

- Fewer Bearings, Sprockets, and Chains

- Fixed, Laser-cut, Pressure Racks with No-Stop Bolts

- Maintenance-free Gearmotors

- Lifetime Lubricated Bearings

Technical Support Services

Product Support Services

Product Features and Benefits

Get in touch

Interested in Our Robotic Automation Solutions?

Need assistance with one of our Robotic Automation products? Whether you’re looking for service, need to order parts, or want a quote on a product, we’re here to assist you.

Send Request